Fabricating Brake Lines: An Unlikely Auto Restoration Favorite

Kira Mundhenk is an apprentice with Steel Wings in Ivyland, Pennsylvania. As she enjoys the process of learning and working in a shop that impressed her from the moment she stepped inside, she is sharing her experiences with the Piston Foundation.

[addthis tool=”addthis_inline_share_toolbox_a1tk”]

Enjoying Automotive Restoration as an Art Form

While I was initially drawn to restoration because of my mechanical curiosity, what really drew me in was discovering how artistic the work actually is. Even on cars that were not originally built by hand, bodywork is sculpture, upholstery is couture, and welded art is prolific. Any time a piece has to be hand fabricated because replacements aren’t readily available, some level of artistic ability comes into play.

My favorite task (for the moment!) is fabricating brake lines. It wasn’t something I thought I would enjoy the first time I was presented with it. Brake lines are very unforgiving, even if you happen to be using modern cunifer lines rather than traditional steel. Once it’s been bent to a certain point, it can’t be straightened and the smallest miscalculation in length can cause it to fit poorly or not at all.

Fabricating Brake Lines

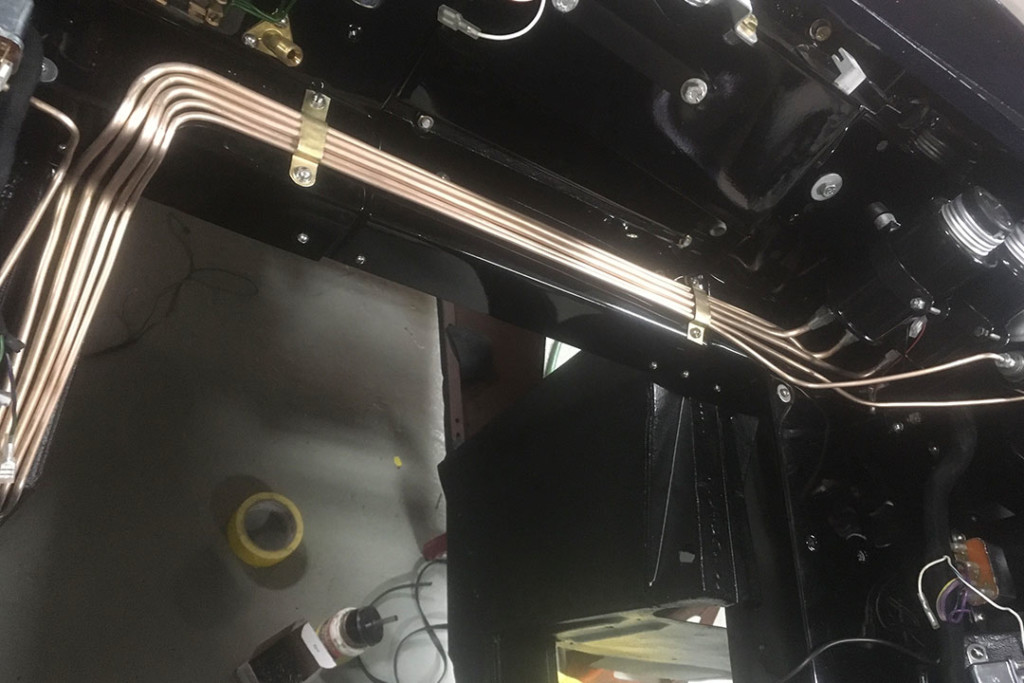

The most effective method of fabrication is to first begin with a pattern. Having the original lines from a car simplifies things, but if the original lines are lost or being rerouted (in a left or right-hand drive conversion, for example) then doing a mockup of the bends required using thin wire is very effective. After the overall length is measured and cut, one end is flared and the bends are worked from there.

Luckily, most of the time it’s possible to test fit throughout the process. Each bend not only has to be at the correct distance but also at the proper angle, and sometimes two bends are so close that the standard bending tools don’t work.

Building Confidence in Addition to Skills

The first lines I made were relatively short, and served as good practice to learn everything that was involved. However, my next job was a dive straight into the deep end. A right-hand drive Aston DB5 has a series of five brake lines all running parallel across the firewall in the engine bay. It’s difficult to get the correct bends in a singular line, but positioning the same series of bends in an increasingly wide radius is a completely different challenge. When I was finished-and satisfied-with those lines, I had a high degree of confidence moving forward.

Recently, I fabricated the brake lines for a DB4 that our shop constructed as a purpose-built race car, and those lines were completely unique to the car. Keeping it as tidy as possible required a lot of creativity, and I was able to use the skills I’d acquired in making parallel lines that flowed nicely.

Working in restoration requires much more than mechanical knowledge learned in a classroom, and I think that as simple as they may seem, brake lines truly showcase that fact.

Donate

Today

Support skilled trade education for future auto restoration technicians.

Campaigns

Give to What You Love

Make a gift that helps the next generation access the education and training they need to begin a career as a classic car technician. Gifts of any size are appreciated and will be used to fund our scholarship and apprenticeship programs.

Sponsor a Piston Scholar

Piston Foundation scholarships are awarded to aspiring technicians to help them begin an auto restoration career. Give to the car culture you love. 100% goes to fund scholarships.

Cars for Piston Scholars

Turn your collector car into education and hands-on training for aspiring collector car technicians. Your car can change lives. 100% goes to fund scholarships.

Give to What You Love

Make a gift that helps the next generation access the education and training they need to begin a career as a classic car technician. Gifts of any size are appreciated and will be used to fund our scholarship and apprenticeship programs.

Sponsor a Piston Scholar

Piston Foundation scholarships are awarded to aspiring technicians to help them begin an auto restoration career. Give to the car culture you love. 100% goes to fund scholarships.

Cars for Piston Scholars

Turn your collector car into education and hands-on training for aspiring collector car technicians. Your car can change lives. 100% goes to fund scholarships.

Subscribe

Sign up for our monthly email with stories, updates, and volunteer opportunities.