Advice for Future Collector Car Technicians from Speedsport Tuning

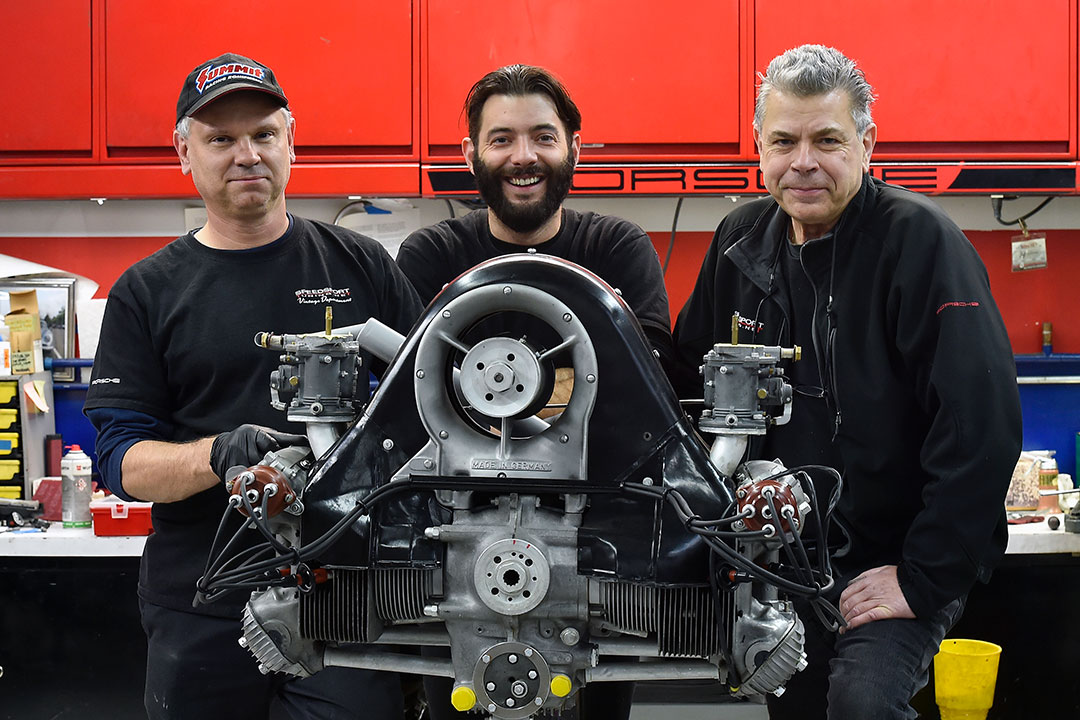

The team at Speedsport Tuning in Danbury, Connecticut, took time out from performing award-winning restorations, race car prep, and service on a wide range of European cars to offer advice to men and women who want to build careers in the skilled trades of the collector car industry.

By Jeff Mason

April 11, 2022

Set Goals. Crush Them. Then, Repeat.

“When I was in high school, there was no help for a kid who wanted to get into this field,” Porsche Service Manager Marc Carson said. “Guidance counselors could help students apply to colleges but, for the trades, there was nothing. I was left to find the schools that could train me and applied on my own.”

Years later, when asked to speak at career day he told students how to approach the future by looking beyond the immediate next step of higher education. “Pick a goal for what you want to do. For me, I was set on working with VW cars.”

At WyoTech, a technical college in Laramie, Wyoming, Carson discovered the VW program and set his next goal. “I started picking dealers in my area that I wanted to work for. I landed the exact job I wanted to land because I had focus. There’s something to be said about having a broad skill set. That’s helpful going in. That and a direction means you’re not overwhelmed with massive amounts of information when you start working on these cars.”

What matters is doing good work for yourself and teaching others around you so the team functions well.

Matt Rosati, vintage service manager, agreed, “Having a goal keeps me motivated. My goal was to not do tires and brakes for a living. Now I build million-dollar engines. If you’re good enough, you can go into specific niches and build whole cars or just transmissions or engines.”

Bryan Shute, crew chief and race department director with Speedsport Tuning, describes himself as a late starter. “I went to UTI when a friend decided to go there. I got a free ride thanks to the National Guard and found learning easy. When one of my instructors suggested the Porsche program, I figured there’d be good pay and prestige. I graduated and thought I was the baddest guy on the planet.”

“There’s Always One More Thing to Learn” – Steve Jobs

“I thought that school taught me a lot more than it did,” Carson said. “My perspective changed two to three weeks into working at the dealership and I discovered how much I would learn on the job.”

“You have to be willing to put the time in,” Bryan Lagas, principal at Speedsport Tuning, said. “Some kids come out of tech school and think they’ll end up here, making $150,000 on day one. That’s not the usual case. Students can learn a lot out of books and from good teachers but, once they’re out in the real world, facing real world problems, they find they have a lot to learn and it takes time before you’re qualified.”

Shute cautioned. “Stay focused and humble. Don’t get too cocky. What matters is doing good work for yourself and teaching others around you so the team functions well.”

“The learning process continues until the day you die.” – Kirk Douglas

“Don’t be afraid to say, ‘I don’t know,’” Porsche Service Advisor Benjamin Smith advised. He earned a degree in business administration prior to working at Speedsport Tuning. “There is a whole other side of these operations that aren’t about nuts and bolts or spinning wrenches and are equally important. My job fits between our customers and technicians. I need to understand what the mechanics are doing. That means I also need the wherewithal and humility to say I don’t know so I can learn. If I can explain something to the customer so he or she has a good experience during the interaction, they’ll know they’ve trusted a quality shop. I’m blessed to be surrounded by the best who have answers to share.”

You learn a lot no matter what seat you fill.

Carson explained, “Collectively, someone has the knowledge or a connection has it. Being able to admit you don’t know the answer and work with that as your limitation means you can figure out the best way to find that answer. You’ll grow as you solve the immediate problem.”

No One Makes It To The Finish Line Alone – Piston Foundation

“We interact in this environment,” Lagas described how Speedsport Tuning’s approach tends to create better techs out of techs that are already very good. “It’s not about making money and getting cars out the door. It’s about working as a team and sharing our knowledge and hundreds of years of combined experience. That’s what makes us strong.”

“The key to a good shop is a tight-knit community,” Shute pointed out. “Resources are important. We have many people outside of this shop that we can ask and there are Facebook mechanic pages where you can find advice on how to fix something. There’s always technical assistance somewhere. These cars are complicated.”

Never Stop Doing Your Best Just Because Someone Doesn’t Give You Credit

“Having access to an honest and reliable mechanic is important,” Shute addressed the stigma associated with an industry that demands a high level of skill from anyone who wants to be successful as an automotive technician or restoration specialist. “That we’re considered the lowest of the low is insane. We’re not here to rob customers.”

He feels most people in the industry exhibit values such as integrity as well as mechanical skills, although not all customers have the chance to observe this first-hand. “In the race shop, we are face-to-face with the customer right after we work on the car. You don’t get that working in a dealership.”

You need experience as well as know-how to be successful there, just as you do when working on modern street cars.

“When the customer drives at 150 mph, all his confidence is coming from these guys,” Lagas said. “Talk about pressure. If we make a mistake because we have an off day, a lot is at risk.”

According to Lagas, that attitude is not just present in the race shop. “I feel everyone in this building has that level of commitment. Every time a car leaves the shop, a life is on the line. If you’re working on a vintage car, you might be working on a museum-quality asset. You have to have a lot of skills in addition to understanding how nuts and bolts and electricity work.”

The Best View Comes After the Hardest Climb

Smith admitted, “There are going to be days that beat you up but if you keep your eye on the prize and keep learning everything you can, this work easily squashes being a parts changer. You can use what you know and take that to a place like Speedsport Tuning where we help each other through the tough days and there’s a great opportunity on the other side.”

Carson recommended, “I’d tell kids to get as much training as they can. Go to classes and get the certifications. Never turn down training if the dealership is paying you to learn. You can market yourself when it’s time for a change. On a resume, training shows eagerness to learn and grow and helps you in the long run.

Success Is About Taking Advantage of Opportunity – Mike Ditka

“The massive labor shortage is the biggest problem we face as an industry,” Lagas said. “For decades, nobody talked about working on cars or with their hands. You went to college or you just weren’t successful. College offers a lot of possibilities but it’s not there to get you into a trade, especially something specialized like the automotive field.”

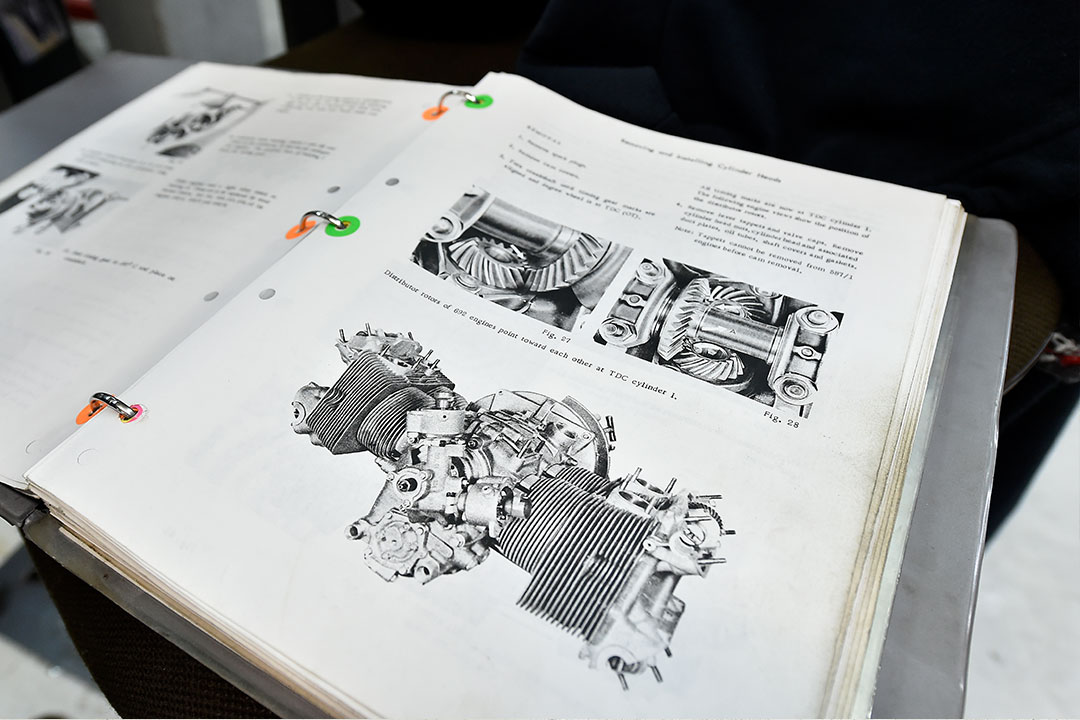

He recognizes that 40 or 50 years ago, educational requirements were lower compared to what is needed to work on cars today. “You could learn on the job because motors were simpler. There were carbs not computers. At a racetrack, we’re working on the same level of tech that you find in a brand new street car, then one step beyond that with telemetry and data acquisition. You need experience as well as know-how to be successful there, just as you do when working on modern street cars.”

“It’s hard to find good people. We have a really solid team but it’s taken years to develop. Skills alone are not enough to make you fit in with the culture that a shop is trying to build.”

Automotive restoration presents a similar problem for leaders like Lagas. “As the older generation retires or switches industries because they’re burned out, there is no new blood to fill the void. People don’t know what a carburetor is, much less how to build or tune one. They can’t diagnose the problem because they can’t plug a scan reader into the car. We’re up against it and will be for decades to come, which is a problem but even more so for the specialized niche work we do.”

Opportunity is Missed by Most People Because It Is Dressed in Overalls and Looks Like Work – Thomas Edison

Lagas said, “There are so many other roles in this industry that are necessary, different levels of managers and, of course, the people who work in parts. We all present skills in different ways. Ben is a perfect example of someone who doesn’t work directly on the cars but someone we rely on.”

“You learn a lot no matter what seat you fill,” Carson said.

“We need good people and can offer a lot in return,” Lagas said. “It’s important for an organization like the Piston Foundation to help men and women who might not otherwise consider a career with a shop like us to find out what might be waiting for them. Heck, women can do this work and, maybe if we could get more of them into this field, we’d solve the problem in no time!”

Donate

Today

Support skilled trade education for future auto restoration technicians.

Campaigns

Give to What You Love

Make a gift that helps the next generation access the education and training they need to begin a career as a classic car technician. Gifts of any size are appreciated and will be used to fund our scholarship and apprenticeship programs.

Sponsor a Piston Scholar

Piston Foundation scholarships are awarded to aspiring technicians to help them begin an auto restoration career. Give to the car culture you love. 100% goes to fund scholarships.

Cars for Piston Scholars

Turn your collector car into education and hands-on training for aspiring collector car technicians. Your car can change lives. 100% goes to fund scholarships.

Give to What You Love

Make a gift that helps the next generation access the education and training they need to begin a career as a classic car technician. Gifts of any size are appreciated and will be used to fund our scholarship and apprenticeship programs.

Sponsor a Piston Scholar

Piston Foundation scholarships are awarded to aspiring technicians to help them begin an auto restoration career. Give to the car culture you love. 100% goes to fund scholarships.

Cars for Piston Scholars

Turn your collector car into education and hands-on training for aspiring collector car technicians. Your car can change lives. 100% goes to fund scholarships.

Subscribe

Sign up for our monthly email with stories, updates, and volunteer opportunities.